OSDA Blog

Sep

14

X-Ray Inspection Capabilities

Reasons to choose X-Ray Services:- New product introduction

- Non-destructive test for optically hidden joints

- (e.g. BGAs) & internal package details (e.g. wire bonding)

- Field failure analysis

- Process development

- Production quality control

- Set-up changes

- Verification for Rework Process

OSDA has chosen an X-Ray machine, that has the ability to view the component from an Oblique view.

Why does this matter?-

1. The solder ball shape can obscure pad detail if you only look from above

2. You may see truncation at top and bottom of ball as evidence of good reflow

3. It is also important to be able to look at the component from different views. One view may show the component as passing, but then when looked at from a different angle, defects may be observed. Angled views show ball shape variation better.

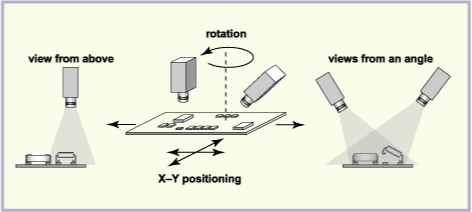

4. OSDA equipment has the ability to view obliquely and from different views. X-Ray Abilities Diagram

Working with OSDA

How Our New Machine Provides You With Results

- All premium quick turns will have X-Ray as part of the process.

- Assures soldering defects are immediately eliminated as defects.

- Available as an option for both standard quick turn and production orders.

- Combined with our AOI testing, assures manufacturing defects can almost be eliminated as the cause of test failures.