Electronic Assembly You Can Depend On

OSDA is committed to continuous quality improvement. Since OSDA is a quick turn specialist, it needs to have a learning curve of zero. Meaning that we process a number of new assemblies weekly and with required deliveries of 4 days or less. With this sort of restraint we do not have the luxury of time to “learn” how to do something right, we need to do it right the first time.

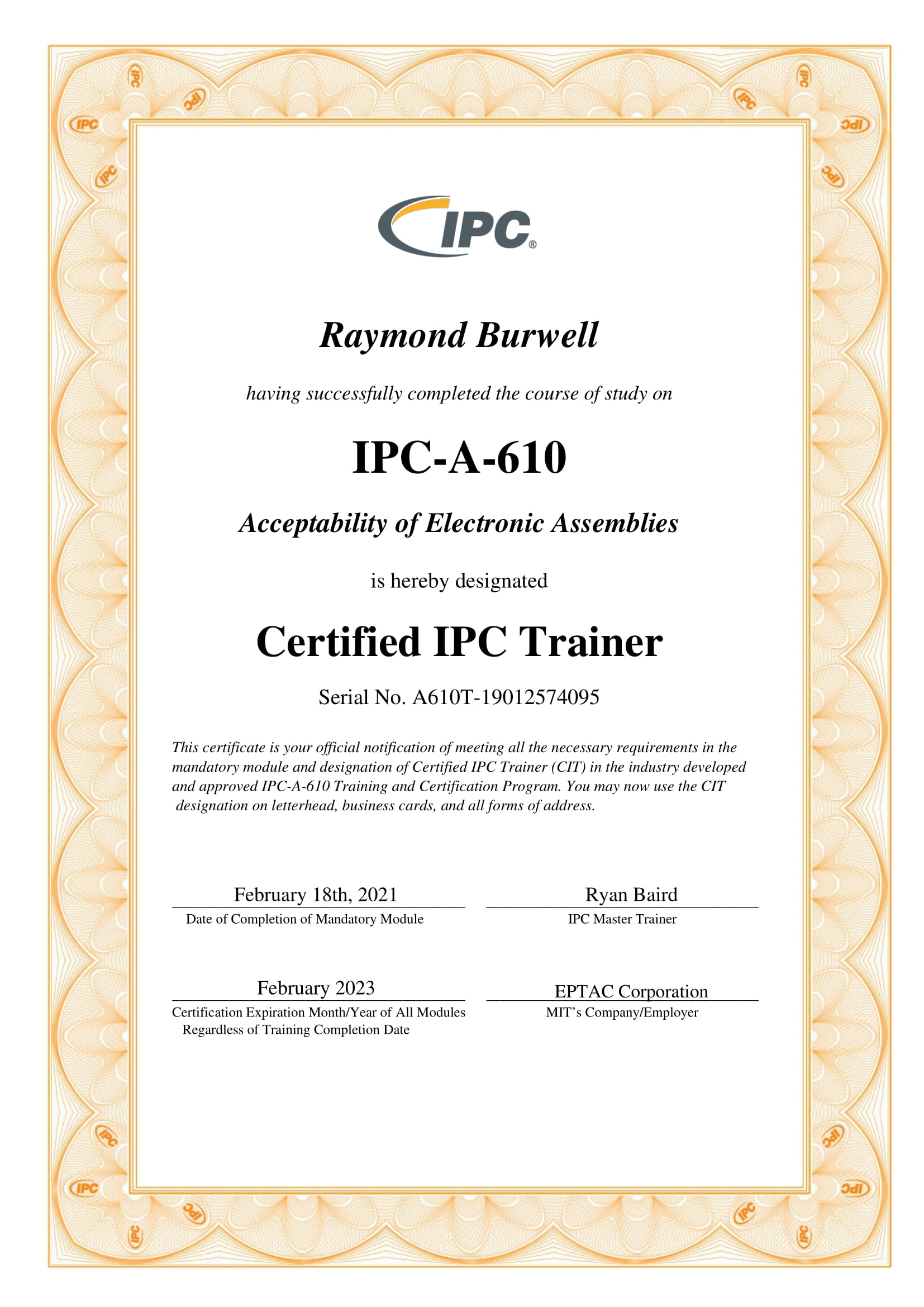

In support of the learning process for Quality improvement, OSDA participates in the global quest for consistent processing and standards that support this desire. OSDA currently has ISO – 9001, ISO – 13485, and an IPC certified trainer for IPC -610.

Engineers are always on a tight schedule to introduce new products, on time and in working condition. OSDA can provide consistency of service including quick turn but also rapid delivery that works out of the box. If this is the type of service you have been searching for, give us a call and we will help you meet your scheduling demands, whether they are for supporting a new product introduction or meeting the timelines for your trade show exhibits.

Certification 1.

ISO 9001:2015

ISO 9001:2015 specifies requirements for a quality management system where an organization •Needs to demonstrate its ability to consistently provide product that meets customer and applicable statutory and regulatory requirements, and

•Aims to enhance customer satisfaction through the effective application of the system, including processes for continual improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

LEARN MORE

CERTIFICATION 2.

ISO 13485:2016

ISO 13485:2016 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer requirements and regulatory requirements applicable to medical devices and related services. The primary objective of ISO 13485:2016 is to facilitate harmonized medical device regulatory requirements for quality management systems. As a result, it includes some particular requirements for medical devices and excludes some of the requirements of ISO 9001 that are not appropriate as regulatory requirements. Because of these exclusions, organizations whose quality management systems conform to this International Standard cannot claim conformity to ISO 9001 unless their quality management systems conform to all the requirements of ISO 9001.

LEARN MORE

CERTIFICATION 3.

IPC-A-610

IPC-A-610, Acceptability of Electronic Assemblies is the most widely used standard published by the IPC. With multiple language versions, it has an international reputation as the source for end product acceptance criteria for consumer and high reliability printed wiring assemblies. An industry developed and approved program that includes training, certification and instructional materials based on the IPC-A-610. This certification demonstrates commitment to customer requirements and greatly assists any company dedicated to ISO-9000 or other quality assurance initiatives. This training and certification has immediate recognition, legitimacy and value throughout the electronics industry.

LEARN MORE

CERTIFICATION 4.

ITAR

International Traffic in Arms Regulations (ITAR) is a set of U.S. Government regulations that requires all manufacturers, exporters, and brokers of defense articles, defense services or related technical data to be ITAR compliant.

LEARN MORE

CERTIFICATION 5.

SIX SIGMA GREEN BELT

The Six Sigma methodology focuses on eliminating problems by analyzing the processes that create them. The ultimate goal is to reduce process defects to 3.4 per one million opportunities. Six Sigma works to eliminate errors and improve operations using three general things: metrics, methodology and philosophy.

LEARN MORE

CERTIFICATION 6.

ASQ CQI

An onsite Certified Quality Inspector (CQI) provides support of and under the direction of quality engineers, supervisors, or technicians, use of proven techniques included in the body of knowledge. Under professional direction, the quality inspector evaluates hardware documentation, performs laboratory procedures, inspects products, measures process performance, records data, and prepares formal reports.

LEARN MORE

CERTIFICATION 7.

SAM

A SAM registration is required for any entity to bid on and get paid for federal contracts or to receive federal funds. These include for-profit businesses, nonprofits, government contractors, government subcontractors, state governments, and local municipalities.

LEARN MORE

A Full-Service Electronics Assembly Manufacturing Company

FIND MORE ABOUT OSDA

Want To Learn More? See More About Our Company.

“ Whatever it takes…surface mount, auto feed, hand solder, OSDA will just do it. They are right on the money with their builds. ”

– Project Manager, Fortune 50 Global Manufacturing Company

Array

(

[our-certification-para1] => OSDA is committed to continuous quality improvement. Since OSDA is a quick turn specialist, it needs to have a learning curve of zero. Meaning that we process a number of new assemblies weekly and with required deliveries of 4 days or less. With this sort of restraint we do not have the luxury of time to “learn” how to do something right, we need to do it right the first time.

In support of the learning process for Quality improvement, OSDA participates in the global quest for consistent processing and standards that support this desire. OSDA currently has ISO – 9001, ISO – 13485, and an IPC certified trainer for IPC -610.

Engineers are always on a tight schedule to introduce new products, on time and in working condition. OSDA can provide consistency of service including quick turn but also rapid delivery that works out of the box. If this is the type of service you have been searching for, give us a call and we will help you meet your scheduling demands, whether they are for supporting a new product introduction or meeting the timelines for your trade show exhibits.

[our-certification-para2] =>

[our-certification-para3] =>

[testimonial-text] => “ Whatever it takes…surface mount, auto feed, hand solder, OSDA will just do it. They are right on the money with their builds. ”

– Project Manager, Fortune 50 Global Manufacturing Company

[find_out_more_about_osda_title] => FIND MORE ABOUT OSDA

[find_out_more_about_osda_sub_title] => Want To Learn More? See More About Our Company.

[find_out_links] => Array

(

[0] => Array

(

[find_us_link_title] => OUR PEOPLE

[find_us_link_url] => http://www.osda.com/about-us/our-people/

)

[1] => Array

(

[find_us_link_title] => OUR HISTORY

[find_us_link_url] => http://www.osda.com/about-us/osda-history/

)

[2] => Array

(

[find_us_link_title] => OUR CERTIFICATIONS

[find_us_link_url] => http://www.osda.com/about-us/osda-certifications/

)

)

)

Array

(

[0] => stdClass Object

(

[meta_id] => 1291

[post_id] => 660

[meta_key] => _edit_last

[meta_value] => 1

)

[1] => stdClass Object

(

[meta_id] => 1292

[post_id] => 660

[meta_key] => _edit_lock

[meta_value] => 1642003765:1

)

[2] => stdClass Object

(

[meta_id] => 1294

[post_id] => 660

[meta_key] => _wp_page_template

[meta_value] => template-certifications.php

)

[3] => stdClass Object

(

[meta_id] => 1296

[post_id] => 660

[meta_key] => _dp_original

[meta_value] => 420

)

[4] => stdClass Object

(

[meta_id] => 1431

[post_id] => 660

[meta_key] => _thumbnail_id

[meta_value] => 2126

)

[5] => stdClass Object

(

[meta_id] => 2436

[post_id] => 660

[meta_key] => our-certification-para1

[meta_value] => OSDA is committed to continuous quality improvement. Since OSDA is a quick turn specialist, it needs to have a learning curve of zero. Meaning that we process a number of new assemblies weekly and with required deliveries of 4 days or less. With this sort of restraint we do not have the luxury of time to “learn” how to do something right, we need to do it right the first time.

In support of the learning process for Quality improvement, OSDA participates in the global quest for consistent processing and standards that support this desire. OSDA currently has ISO – 9001, ISO – 13485, and an IPC certified trainer for IPC -610.

Engineers are always on a tight schedule to introduce new products, on time and in working condition. OSDA can provide consistency of service including quick turn but also rapid delivery that works out of the box. If this is the type of service you have been searching for, give us a call and we will help you meet your scheduling demands, whether they are for supporting a new product introduction or meeting the timelines for your trade show exhibits.

)

[6] => stdClass Object

(

[meta_id] => 2437

[post_id] => 660

[meta_key] => our-certification-para2

[meta_value] =>

)

[7] => stdClass Object

(

[meta_id] => 2438

[post_id] => 660

[meta_key] => our-certification-para3

[meta_value] =>

)

[8] => stdClass Object

(

[meta_id] => 2439

[post_id] => 660

[meta_key] => testimonial-text

[meta_value] => “ Whatever it takes...surface mount, auto feed, hand solder, OSDA will just do it. They are right on the money with their builds. ”

- Project Manager, Fortune 50 Global Manufacturing Company

)

[9] => stdClass Object

(

[meta_id] => 4988

[post_id] => 660

[meta_key] => find_out_more_about_osda_title

[meta_value] => FIND MORE ABOUT OSDA

)

[10] => stdClass Object

(

[meta_id] => 4989

[post_id] => 660

[meta_key] => _find_out_more_about_osda_title

[meta_value] => field_57284fd905c54

)

[11] => stdClass Object

(

[meta_id] => 4990

[post_id] => 660

[meta_key] => find_out_more_about_osda_sub_title

[meta_value] => Want To Learn More? See More About Our Company.

)

[12] => stdClass Object

(

[meta_id] => 4991

[post_id] => 660

[meta_key] => _find_out_more_about_osda_sub_title

[meta_value] => field_57284fec05c55

)

[13] => stdClass Object

(

[meta_id] => 4992

[post_id] => 660

[meta_key] => find_out_links_0_find_us_link_title

[meta_value] => OUR PEOPLE

)

[14] => stdClass Object

(

[meta_id] => 4993

[post_id] => 660

[meta_key] => _find_out_links_0_find_us_link_title

[meta_value] => field_5728501805c57

)

[15] => stdClass Object

(

[meta_id] => 4994

[post_id] => 660

[meta_key] => find_out_links_0_find_us_link_url

[meta_value] => http://www.osda.com/about-us/our-people/

)

[16] => stdClass Object

(

[meta_id] => 4995

[post_id] => 660

[meta_key] => _find_out_links_0_find_us_link_url

[meta_value] => field_5728503d05c58

)

[17] => stdClass Object

(

[meta_id] => 4996

[post_id] => 660

[meta_key] => find_out_links_1_find_us_link_title

[meta_value] => OUR HISTORY

)

[18] => stdClass Object

(

[meta_id] => 4997

[post_id] => 660

[meta_key] => _find_out_links_1_find_us_link_title

[meta_value] => field_5728501805c57

)

[19] => stdClass Object

(

[meta_id] => 4998

[post_id] => 660

[meta_key] => find_out_links_1_find_us_link_url

[meta_value] => http://www.osda.com/about-us/osda-history/

)

[20] => stdClass Object

(

[meta_id] => 4999

[post_id] => 660

[meta_key] => _find_out_links_1_find_us_link_url

[meta_value] => field_5728503d05c58

)

[21] => stdClass Object

(

[meta_id] => 5000

[post_id] => 660

[meta_key] => find_out_links_2_find_us_link_title

[meta_value] => OUR CERTIFICATIONS

)

[22] => stdClass Object

(

[meta_id] => 5001

[post_id] => 660

[meta_key] => _find_out_links_2_find_us_link_title

[meta_value] => field_5728501805c57

)

[23] => stdClass Object

(

[meta_id] => 5002

[post_id] => 660

[meta_key] => find_out_links_2_find_us_link_url

[meta_value] => http://www.osda.com/about-us/osda-certifications/

)

[24] => stdClass Object

(

[meta_id] => 5003

[post_id] => 660

[meta_key] => _find_out_links_2_find_us_link_url

[meta_value] => field_5728503d05c58

)

[25] => stdClass Object

(

[meta_id] => 5004

[post_id] => 660

[meta_key] => find_out_links

[meta_value] => 3

)

[26] => stdClass Object

(

[meta_id] => 5005

[post_id] => 660

[meta_key] => _find_out_links

[meta_value] => field_5728500a05c56

)

[27] => stdClass Object

(

[meta_id] => 11691

[post_id] => 660

[meta_key] => _our-certification-para1

[meta_value] => field_5d794970e11d5

)

[28] => stdClass Object

(

[meta_id] => 11692

[post_id] => 660

[meta_key] => _our-certification-para2

[meta_value] => field_5d794982e11d6

)

[29] => stdClass Object

(

[meta_id] => 11693

[post_id] => 660

[meta_key] => _our-certification-para3

[meta_value] => field_5d794987e11d7

)

[30] => stdClass Object

(

[meta_id] => 11694

[post_id] => 660

[meta_key] => _testimonial-text

[meta_value] => field_5d79498be11d8

)

)