Companies we have worked with include:

- Ascend corporation

- avidia systems

- integrated systems

- plasmaco

- sirocco systems

- sycamore systems

- mangrove systems

- otis elevator

- panasonic

- ibm

- zygo corporation

- oem controls

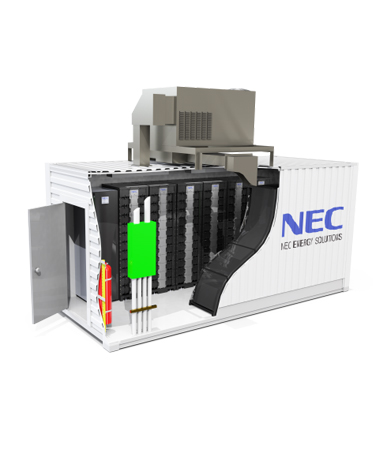

- nec infrontia, inc.

- trans-liate, inc.

- preferred electronics

- phillips medical

- mango dsp

- drs